MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Aug 26, 2011 22:00:53 GMT -5

Tin cut and template made. Used tape to mark my cutting lines on the original tin. Hand shears, jig saw and dremeal to do the cutting and touch up.   |

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Aug 26, 2011 22:07:41 GMT -5

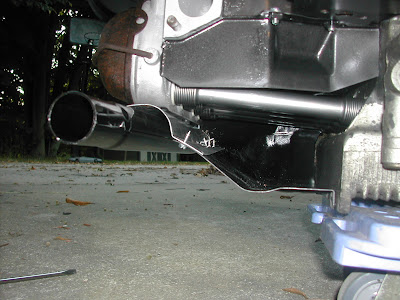

Shaped and held on with sheet metal screws. Suprised how well this worked.  Number 3/4 tin mounted with J tube   Tin 1/2 side  Painted in high temp paint, silver is what I had so I used it  Matches my heads.  Have to admit, this took me a long time. Probably 5 hours. |

|

tarrich

1500sp

Posts: 193

Joined: Aug 12, 2009 21:13:48 GMT -5

|

Post by tarrich on Aug 26, 2011 22:51:55 GMT -5

Still looks awfully close to the head and j- tube If it makes actual contact with the J- tube and the head it would bridge and transfer the heat instead of isolating the fan air from the heat radiating from the exhaust. If I understand the original VW design there was a layer of tin in T3 "cool tin wrapping around the head with air gap or just the type1 deflector plates hanging from the studs and the heater boxes had the outer shell to contain the exhaust heat for the cabin and support the sleds. The J- tube would have to be double walled to achieve the same thermal isolation. Is there a risk of the sheet-metal screws vibrating loose?

|

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Aug 28, 2011 19:12:23 GMT -5

I doubt the sheet screws will come loose but this is until I get a weld on the extra piece anyway. After a little more bending it maintains a nice gap with no touches. Even if it did touch, the head can handle that I'm sure, considering the amount of heat it endures for the combustion itself. The shield serves two purposes, one protecting the pushrods and second maintaining the integrity of the air flow through the cylinders and out the back. Without that piece air flow would be interrupted by turbulence or exit the sides and potentially back up into the fan. You're right the stock heater boxes act to fill that side gap normally but even then left an air space considerably larger so it's not a perfect setup either way. This setup has a much tighter tolerance that the stock one so if anything should help with cooling. My thoughts anyway.  |

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Aug 28, 2011 20:08:50 GMT -5

|

|

67type1

1600dp

Remembering the past.... liv'n the Dream

Posts: 666

Joined: Mar 18, 2011 19:05:44 GMT -5

|

Post by 67type1 on Aug 29, 2011 7:34:17 GMT -5

Mike, quite a difference from start to finish. Nice Job!

|

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Sept 1, 2011 21:18:43 GMT -5

After long struggles with the rear engine compartment seal I've decided the best way to install it is with a flat screw driver and just work your way from one end to the other poking it in slowly.

It went fairly quick once I stopped trying to slide it in with soapy water. If all goes well on Friday I'll have the engine back in.

|

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Sept 2, 2011 11:47:34 GMT -5

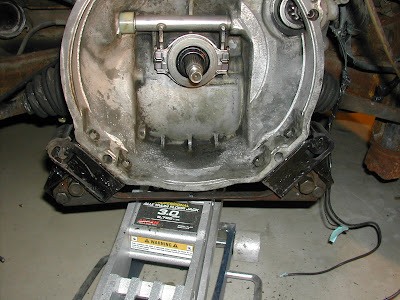

Geez I just want to put the engine in  Removed the transmission horn bolts to get new rubber mounts on and they came out real hard. After inspection appears they were pretty buggered up. Probably installed with an air hammer and cross threaded. The bolts won't go back in. |

|

teamafx

1600dp

I am in group #1

Posts: 1,341

Joined: May 29, 2010 15:33:28 GMT -5

|

Post by teamafx on Sept 2, 2011 12:07:35 GMT -5

Did it mess up the frame horns or the bolts? Or both?

|

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Sept 2, 2011 19:29:54 GMT -5

Bolts looked ok. Called around and found 1 tap 18 x 1.5mm at Napa for $5. Took some serious knuckler busters to tap the horns but got it done. 5 hours later mounts are in.   |

|

teamafx

1600dp

I am in group #1

Posts: 1,341

Joined: May 29, 2010 15:33:28 GMT -5

|

Post by teamafx on Sept 2, 2011 20:21:24 GMT -5

That was a cheap fix. Will you have it in and running tomorrow?

|

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Sept 2, 2011 20:44:29 GMT -5

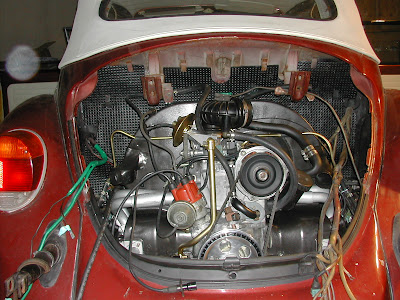

;D ;D ;D ;D ;D  Family effort got it in. I am now very tired, cut and bruised. Right side wiring complete. Lots of wire's to route and hook up. Some I'm not sure what they are any more. Need to install a fuel pressure guage and final hook up on fuel rail. Then test fire and timing. Saturday is family day so won't be running until next week. Soccer tournament in Kalamazoo all weekend. Glad to have it in though. |

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Sept 3, 2011 7:20:00 GMT -5

Darn, forgot I need to cut off and weld the heat risers on my exhaust. So can't put that back on for a bit. No welding skills/tools.

|

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Sept 6, 2011 21:56:52 GMT -5

IT'S ALIVE!!  Fiddled with wires for 2 hours and seem to have them all right. Drained all the old gas. Beauty of the elec fuel pump, just turn on the key and let it empty the tank. Car started immediately after a static timing. Runs very very rough right now. Hopefully it's just a timing issue. Let it run only for 45 seconds to get the oil pressurized. Pictures show the new quiet pack peeking out. I really like the sound.   Will clean up timing later this week. Cross my fingers it's just basic tuning and not a full diagnostic of the FI again. |

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Sept 7, 2011 14:26:14 GMT -5

Just read on Samba that the FI engines are designed to be timed with the engine running. Static timing won't work like the older models. You can static time to get it close but then must time at 28 degrees at 3500 rpms with vacuum hoses off. Dwell is evidently critical too, can't just set the point gap at .016.

Interestingly you must also static time initially at 7.5 degree BTDC, not TDC like my Ghia. No clue how they came up with that number.

That might explain the initial rough running. I'm 7.5 degrees off. Can't wait to get home to try it.

|

|