MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Aug 17, 2011 22:06:44 GMT -5

Goofy little springs hold the flaps connecting rod on. Pretty flimsy. Older style while more complicated was more secure. |

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Aug 18, 2011 18:55:12 GMT -5

homemade gaskets, can't get the paper ones anymore  |

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Aug 18, 2011 18:57:10 GMT -5

belt, egr, throttle control, upper throttle body, fuel rail and left injectors installed  |

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Aug 18, 2011 19:02:26 GMT -5

need to test fit the exhaust while it's out just because it's easier, then it's ready to go back in.

Do I need the rear tin on before I put the engine back in?

|

|

67type1

1600dp

Remembering the past.... liv'n the Dream

Posts: 666

Joined: Mar 18, 2011 19:05:44 GMT -5

|

Post by 67type1 on Aug 19, 2011 6:09:48 GMT -5

Look'n good! The rear tin goes on after the engine is in place.

|

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Aug 19, 2011 12:26:32 GMT -5

Any good ideas for what to use to cap off my heater vents on the shroud?

|

|

Pikeman

1500sp

Posts: 338

Joined: Oct 19, 2008 17:30:45 GMT -5

|

Post by Pikeman on Aug 19, 2011 14:19:42 GMT -5

Get to a good hardware store, and in the plumbing dept. you will find rubber caps you can use,held in place with hose clamps.

|

|

67type1

1600dp

Remembering the past.... liv'n the Dream

Posts: 666

Joined: Mar 18, 2011 19:05:44 GMT -5

|

Post by 67type1 on Aug 19, 2011 18:50:19 GMT -5

Paul's suggestion sounds good.

Back in the day we used baby food jar tops. I'm sure they've changed.

|

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Aug 20, 2011 16:52:40 GMT -5

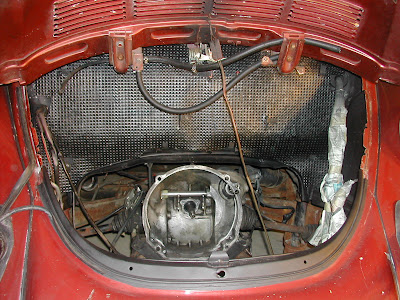

Engine is done and ready to go in. Still need to run new fuel lines, put in the tarboard and change the transmission seal and mounts.

|

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Aug 20, 2011 16:59:46 GMT -5

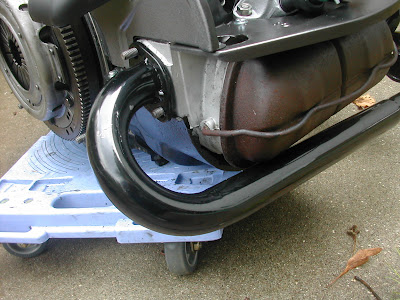

Test fit of the EMPI single quiet pack did not go well. J-Pipes didn't evencome close to fitting. Originally called Chirco and asked if this would fit and they said yes but it's not happening. J-Pipes won't clear the heads, valve covers and lower tin. Purchased it in June, hope they take it back.   Quality of this thing was horrible. So much for going the "inexpensive" route. |

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Aug 21, 2011 19:28:14 GMT -5

looks like I have time for more odds n ends work until I get this exhaust figured out. Was hoping to install it and fire it up this week.  |

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Aug 21, 2011 20:53:50 GMT -5

ordered some german made 7mm FI fuel line for $9 a meter.  This stuff while expensive is considerable better than the 5/16 FI line from Napa or AutoZone. The german stuff is very flexible and easy to route. The Napa stuff is stiff as a board and prone to collapsing any time you bend it. I'm usine the Napa stuff for all the short straight lines and the german stuff for the long lines that have to go around things. I discovered that applying a little heat to the tube with a heat gun would allow it to be shaped just a little so it would handle a curve without collapsing. |

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Aug 23, 2011 18:39:13 GMT -5

After scanning literally hundreds of posts on j tubes I found zero discussion on how to apply a header style exhaust to a FI motor.

I did stumble across one post from a guy who said he had done it. Sent him a PM and he replied same day with how to do it.

It will require some metal fabrication on my part to cut my tin and protect my pushrod tubes and heads from the j tube heat but it will work. J- tubes clear my heads by about 1/2 inch.

I removed all my lower tin and could just sneak the tubes under at which point I successfully got the EMPI header mounted. It actually fit fairly decent.

Clearance of the muffler is a bit tight but I think I'm stuck with that for this style of exhaust. I'm calculating 7 inches from floor to muffler which is exactly the same clearance my rear shock mounts are.

I can now mount the engine and figure out the tin later comfortable that I have a solution.

|

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Aug 23, 2011 18:43:41 GMT -5

Actually on further inspection I'll have to solve the tin fabrication first as the upper tin screws to the lower tin nuts and I can't get to the screws with the engine in the car. Bah. Glad I figured that out now.

|

|

MikeH

1600dp

Posts: 641

Joined: Aug 14, 2008 12:18:22 GMT -5

|

Post by MikeH on Aug 26, 2011 21:55:39 GMT -5

Tarboard on firewall installed, picture doesn't do it justice.  Also front engine compartment seal is in, what a pain. Have attempted the big rear appron seal multiple times and haven't come close to gettting that one in. Gave up and moved on so my engine tin. |

|