|

|

Post by bren on Feb 24, 2010 23:21:10 GMT -5

Clinton, can you explain what is meant by flywheel run out? What did you do to fix it.

I am curious why the center bearing is installed in the above test. I see a gap remaining between the bearing halves, is that a problem at all?

The first case I took to Greg for machining had this exact problem and was not good to use. There was way too big of a gap in the case halves. This was the result of my crank breaking. I had hoped that case was still OK but it wasn't.

I appreciate what you are sharing here. Especially since I am going to try my hand at building a motor very soon here. Thanks, Bren.

|

|

clintonddk

1600dp

Posts: 755

Joined: Oct 7, 2008 18:16:45 GMT -5

|

Post by clintonddk on Feb 25, 2010 18:20:10 GMT -5

Hi Bren,

Flywheel run out is the wiggle of the flywheel. After reading end play I keep the dial indicator on the flywheel and take a reading as I rotate the flywheel 360 degrees. .008" is about the limit of run out I like to see. What I have to do next is figure out if the problem is in the end of the crank or the mating surface of the flywheel. When I figure that out I will take it to Jim Green and have him machine either surface.

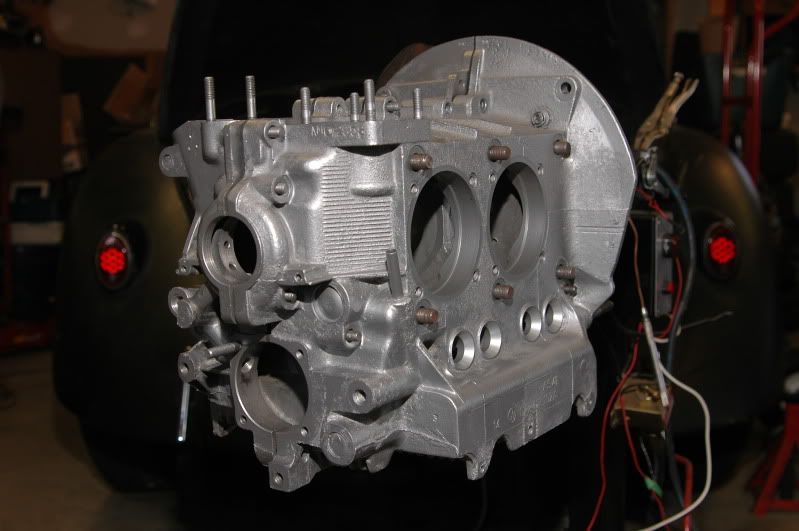

Yes, what I am showing you is the crack in the case halves. yes, if your case wont pull together it is bad. I always bolt a case together and check for this before I have my guy do any work on it because if it does not pull together with out bearings in it it wont ever come together, then after it is returned to me whether it is lined bored or not I install the center main bearing a check it again just to make sure that the bearing isn't going to hold the case halves apart. Not all bearings are the same and this is the reason one should get his bearing from the guy that did the line bore. The other reason I do this is so I know what torque specs the case comes together. I actual have to do this again with a nylon nut because I am sure the torque spec will be different.

|

|

|

|

Post by bren on Feb 25, 2010 22:12:14 GMT -5

Thanks Clinton.

|

|

|

|

Post by 81pumagtc on Feb 25, 2010 22:21:45 GMT -5

Clinton:

Watching this with great interest. My only experience with case haves is with motorcycles. You talk about doing this again with a nylon nut, and I am a little confused. Is this to avoid damaging the case studs?

Confused in East Lansing

a.k.a. Dave Riedle

|

|

clintonddk

1600dp

Posts: 755

Joined: Oct 7, 2008 18:16:45 GMT -5

|

Post by clintonddk on Feb 26, 2010 10:18:14 GMT -5

Sorry for the confusion Dave,

I like to use the nylon locking nuts for an engine like this and I am sure that the torque specs for those nylon locking nuts will be different then using the stock nuts. I hope that this clear things up.

|

|

|

|

Post by bren on Feb 26, 2010 19:36:48 GMT -5

I plan to use the nylon locking nuts. When you find the torque specs for them will you share?

|

|

clintonddk

1600dp

Posts: 755

Joined: Oct 7, 2008 18:16:45 GMT -5

|

Post by clintonddk on Feb 26, 2010 20:33:16 GMT -5

Hay Bren just get out your torque wrench and your flash light and see for your self ;D Start out with 25 foot ponds and then work your way up to where your case halves are mated  |

|

dansam

1600dp

Posts: 2,434

Joined: Oct 25, 2008 7:23:39 GMT -5

|

Post by dansam on Feb 26, 2010 20:49:11 GMT -5

Always fun watching other peoples builds. Always learing  |

|

|

|

Post by rochester73super on Feb 26, 2010 21:18:13 GMT -5

Curious to know the difference in the torque specs.

|

|

|

|

Post by 81pumagtc on Feb 26, 2010 23:06:21 GMT -5

Clinton: Nylocks make sense to keep torqued, but I personally would be a little concerned about heat performance. Nylocks are only rated to 250 degrees, but that is for total failure of the insert. They loose a sizable percentage of their vibration resistance at around 180 to 230 degrees. I have had this issue in the past with some powdercoating equipment I designed. I ended up using SPS Flexloc nuts instead. If you have never seen them before, they are a locking nut with a split top that does not damage threads, and since they are MIL spec, they have accurate torque specs available. They are rated to 750 degrees, which would make me a bit more comfortable. Price for a 10mm runs from $.70 to $1.60 per nut for 18-8 stainless, about half that for cadmium, depending on source and quantity. that runs about twice the cost of good Nylocks. These are not the same as interrupted thread nuts, which have been known to have slightly varying torque specs...and only the Toplock versions are reusable. If you have to disassemble things, Flexloc fasteners are completely reusable. Most folks I know consider it to be bad form to reuse a Nylock because the insert deforms, and that throws off accurate torque specs the second time. Here is a catalog: www.spstech.com/aero/prod_lit/flexloc_cat_sp1040.pdfJust my two cents worth here. Give me a shout if you have any questions. Dave Riedle |

|

clintonddk

1600dp

Posts: 755

Joined: Oct 7, 2008 18:16:45 GMT -5

|

Post by clintonddk on Feb 27, 2010 8:39:53 GMT -5

Dave those Flex Lock nuts are very interesting looking. I personally have had good luck with the nylon lockers. I had reused the set on my own engine several times. They are on my turbo engine right now. Then again I have never checked the torque on them after running the engine, all I know is that they are always tight when I go and tear my engine back down. I would be interested in seeing a set of those Flex Lockers where do you find them Mid State and Bolt?

|

|

|

|

Post by 81pumagtc on Feb 27, 2010 9:54:17 GMT -5

Clinton: I don't know if Mid-State has them. I usually ordered them in Stainless, but I may have a couple laying around, maybe 10mm. If so I'll drop a couple off. I have used Nylocks for years, and have tons of them on the Puma, but nothing on the engine. I'll bet they are just fine, but where I was using them was actually inside a powder coating oven, which gets hots. I'll bet VWs don't get that hot.  Also, there are LOTS of different levels of quality. The stuff you get from Midwest Fasteners are not bad (sold Ace, Mid-West, etc.), but you can get some real nasty Chinese or Indian pieces that don't really use nylon for the insert. I'll bet you don't buy your fasteners at TSC for that reason. These don't work at all for me, I would rather use a wave washer. Also, if you use threads that are really sharp, they actually begin to cut or abrade the insert, which reduces the physical material used to provide the locking action. I know I'm a bit anal about it, but I was always used to safety wiring the really important bits and pieces on the race cars. (When I tried to destroy them, I just hit things. :-) ) Really old school here...heck, I'm just old! There are so many really cool fasteners out there and so little time... Dave |

|

clintonddk

1600dp

Posts: 755

Joined: Oct 7, 2008 18:16:45 GMT -5

|

Post by clintonddk on Mar 23, 2010 21:34:36 GMT -5

Fresh Paint  |

|

Ruffuss

1600dp

Posts: 2,795

Joined: Jun 25, 2008 19:13:16 GMT -5

|

Post by Ruffuss on Mar 24, 2010 4:30:23 GMT -5

COOL!!

|

|

dansam

1600dp

Posts: 2,434

Joined: Oct 25, 2008 7:23:39 GMT -5

|

Post by dansam on Mar 24, 2010 5:53:07 GMT -5

Have used the nylon lock nuts on 2 engines and never had any issues that Im aware of. I bought that kit. One kit from MAM and one from JCW both served me well and had all the nuts I needed to build the engine. I used stock torque specs for the 1 as it was a 1641 with stock studs and I used gene berg specs for my present engine as it is does not use stock studs.

|

|